Screening is an important process in many industries and applications. Whether it is for filtering materials, protecting areas, or providing security, the choice of screening material plays a crucial role in its effectiveness. Among the many options available, custom wire mesh stands out as an ideal solution. This article explores why custom wire mesh is essential for durable and reliable screening and how it can benefit various needs.

Understanding Custom Wire Mesh

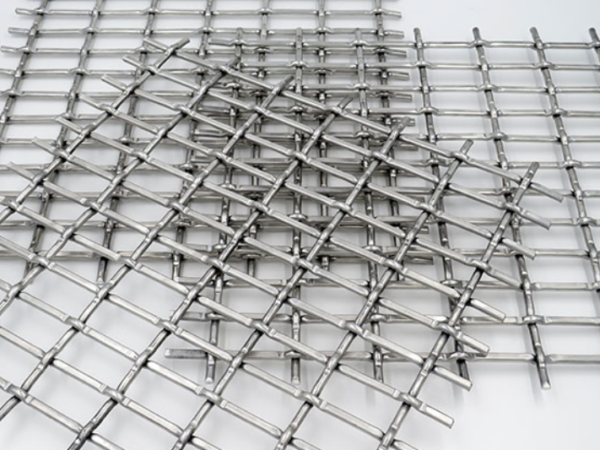

Custom wire mesh refers to wire mesh products that are made to specific requirements. Unlike standard wire mesh, which comes in fixed sizes and materials, custom Wire mesh allows users to choose the type of wire, mesh size, thickness, and pattern based on their unique screening needs. This flexibility ensures that the mesh fits perfectly and performs well for the intended purpose.

The customization process means that the wire mesh can be designed to meet specific durability standards, resist environmental factors, and handle different types of materials or forces during use. This tailored approach makes custom wire mesh far more effective and reliable than generic alternatives.

Durability Through Tailored Material Selection

One of the key reasons custom wire mesh is essential for durable screening is the ability to select materials that suit the environment and application. Wire mesh can be made from various metals such as stainless steel, galvanized steel, aluminum, or copper. Each material has its strengths and weaknesses, and choosing the right one impacts the mesh’s lifespan and performance.

For example, stainless steel custom wire mesh is highly resistant to corrosion and is perfect for outdoor or harsh environments. Galvanized steel provides a good balance of strength and rust resistance at a lower cost. By selecting the appropriate material, the custom wire mesh lasts longer, reducing the need for frequent replacements and maintenance.

Reliability Through Precise Mesh Design

The reliability of screening depends greatly on the mesh size and pattern. Custom wire mesh allows precise control over these details. Mesh size determines what can pass through the screen and what is filtered out. Whether it is tiny particles, insects, or larger debris, having the right mesh size is critical for effective screening.

In addition, the pattern and thickness of the wire contribute to the overall strength and stability of the mesh. A carefully designed custom wire mesh can withstand pressure, impacts, and wear without deforming or breaking. This reliability ensures that the screening process is consistent and efficient over time.

Adaptability to Different Screening Needs

Every screening project has its own set of requirements. Some may need very fine mesh to filter small particles in the food or pharmaceutical industry. Others might require heavy-duty mesh for security fencing or construction barriers. Custom wire mesh can be adapted to all these situations.

This adaptability means businesses and individuals can get exactly what they need without compromise. Whether the project demands a specific size, shape, or material finish, custom wire mesh can be produced accordingly. This ensures maximum functionality and satisfaction with the screening solution.

Cost-Effectiveness in the Long Run

While custom wire mesh may sometimes have a higher upfront cost compared to off-the-shelf options, it proves to be more cost-effective in the long run. The durability and reliability reduce the chances of damage and failure, which means fewer repairs and replacements.

Moreover, because custom wire mesh is designed specifically for the intended use, it improves efficiency in screening operations. This can save time and labor costs. Ultimately, investing in custom wire mesh provides better value by delivering longer-lasting and dependable screening.

Enhanced Safety and Security

In applications where safety and security are important, custom wire mesh offers additional benefits. The strength and quality of the mesh can be designed to meet specific security standards. This is crucial for areas that require protection against intrusion or to keep materials safely contained.

By customizing the wire thickness and mesh pattern, the mesh becomes harder to cut or damage. This added security makes custom wire mesh a trusted choice for many industries, including construction, manufacturing, and public safety.

Conclusion

Custom wire mesh is an essential choice for anyone seeking durable and reliable screening solutions. Its ability to be tailored to specific materials, sizes, and patterns ensures superior durability and consistent performance. The adaptability to different applications and long-term cost savings further highlight its importance.

Choosing custom wire mesh means investing in a product that is made to fit your needs perfectly, offering strength, reliability, and security. Whether for industrial use, security, or filtration, custom wire mesh provides a trusted screening solution that stands the test of time.